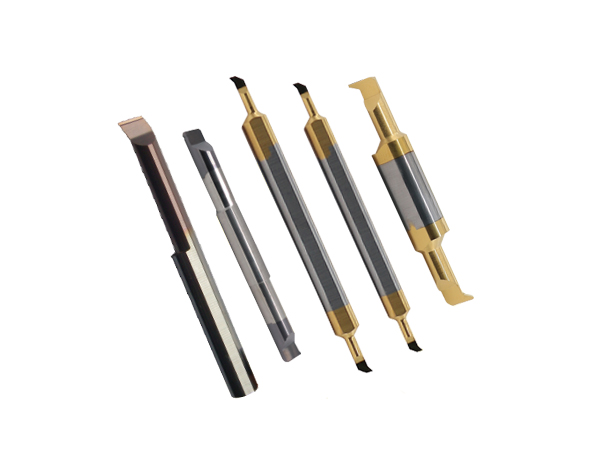

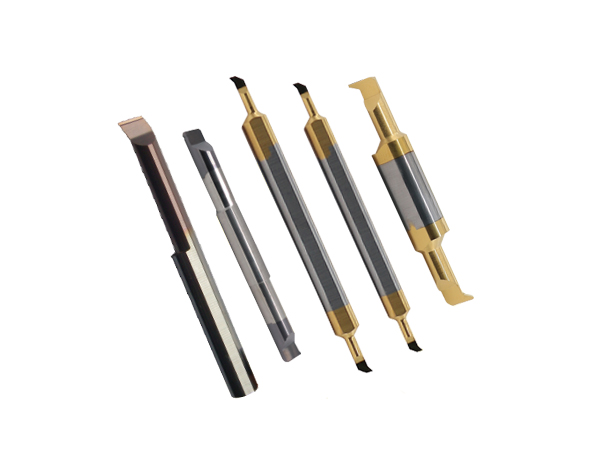

Focus on tool design and R & D

Precision cutting tools from Germanymanufacturer

+86 133-9231-4699

Focus on tool design and R & D

+86 133-9231-4699

Get the right balance

Design engineers have thankless jobs. They never stop spending energy to constrain tolerances and improve accuracy to fight failures and downtime. They have improved the design accuracy to about 1 micron year after year. They are perfect watchers.

But when the tools are not properly balanced, their thorough and careful attention to detail produces waste. Machining parts with unbalanced tools is similar to shooting your own feet. The tool will wear out normally after performing the design task. However, the tool designed to perform that task is assumed to be well-balanced. If you use an unbalanced tool for this job, you are introducing new levels of wear, not only for the tool and spindle but also for the parts to be executed. Unbalance can have several effects: it can introduce additional vibrations to the spindle and its components, it will wear the tool irregularly, it can reduce the life of the tool and reduce the quality of the finished product.

Correct imbalance

The main reason for the imbalance of the knife handle is: there is a defect in the knife body, and the design of the knife is tired. Generous. 惚匦朐谑圐衣米 Ba Tongrong Huai pattern glue?

A correctly balanced tool can significantly reduce noise and vibration, which increases tool life and better consistency of parts accuracy. The centrifugal force amplifies the vibration caused by the imbalance in a relationship proportional to the square of the speed. The resulting increase in vibration minimizes the life of bearings, bushes, shafts, main shafts, and gears. In addition, if you don't balance the tools, you will run the risk of invalidating the spindle manufacturer's warranty. Many warranties specifically state that the warranty is only valid when there is sufficient evidence that the tools used on the machine tool are correctly balanced. In this respect, tool balancing can cause huge savings.

Before balancing the tool, you need to measure the size of the imbalance and the angular position of each selected correction plane. These variables are measured on two general types of balance machines: non-rotating or gravity machines are used to measure unbalance in a single plane (stationary), while rotating or centrifuges are used to measure single plane and/or two-plane (dynamic) unbalance. balance.

After measuring the size and angle of the unbalance on the correct plane, you can correct it by adding or removing material from the workpiece. For components that are not tools, the most widely used material addition method is to weld counterweights on the components. Other methods for slightly unbalanced components include adding solder to the component body or adding weight in pre-drilled holes.

For the tool, when you determine the imbalance that you measure, you must remove the material to get the correct balance. The easiest and most effective method is drilling. This is a quick adjustment, and the amount of material removed can be precisely controlled. Another option is milling, which is the most effective for balancing thin-walled tools or when shallow cutting is mandatory.

Theoretically, perfect balance can be obtained when balancing tools. In real applications, due to cost considerations and tool limitations, the perfect balance can only be achieved when very lucky. Therefore, the accuracy level must be set to allow a certain amount of residual imbalance to control harmful effects to an acceptable level. The accuracy given in ISO1940 usually produces satisfactory results, but make sure that the standard you implement is suitable for the tool to be balanced. For example, compared to rigid load propellers, machine tools will obviously use different values.

Tool selection and maintenance

Tool balance is not just about measuring imbalance and adding or subtracting weight. Tool selection is very important. Short and light tools are easily balanced to good accuracy, while large and heavy tools are much more difficult and have a tendency to vibrate. You can also save time and reduce costs by choosing a tool holder that has been pre-balanced or pre-processed to the smallest imbalance.

Furthermore, you can reduce the number that must be balanced through regular maintenance and careful handling. Any surface damage of the handle will affect the balance and concentricity. Why? When the rotation speed climbs, the impact of tool holder defects is magnified. If your instrument measures a negligible force at 1,000 revolutions per minute, the force increases by 100 times when the speed is 10,000 revolutions per minute, and 400 times at 20,000 revolutions per minute.

Excellent concentricity is even more important under high-speed spindles, because if the tool does not rotate on the centerline of the spindle, it becomes the primary factor of additional imbalance. But the impact of unbalanced tool holders is also obvious at lower speeds. Small imbalances can cause high forces to damage the spindle bearings of your machining center, and continuous large radial forces can cause early bearing failures and expensive machine tool maintenance costs.

Also, keep in mind that any adjustment (installation or removal of tool components, tightening of nuts, or any slight twisting or welding) requires some degree of balance. Even if the balance of the adjustment interference tool is only a few grams X millimeters, this imbalance is converted into an increase in vibration, causing accelerated tool wear, deterioration of surface finish, and decrease of part shape accuracy (such as loss of roundness or straightness during boring) ).

Appropriate precision = better balance

In addition to the correct maintenance and handling of high-quality tool holders, it is important that the tool components are correctly installed on the machine spindle. In order to obtain a firm and stable connection, the matching spindle taper hole of the tool holder should be as accurate as possible. The difference between a well-fitted toolholder and a poorly matched toolholder is especially obvious at high speeds. You may have the best balanced tool in the world, but if it is not properly connected to the spindle, you are asking for trouble.

When you think that many machining centers sold today are equipped with spindles with a maximum speed of 10,000 rpm or above, you have to infer that the quality of the tool holder must be at the same level as the performance of the spindle. They must be firm, centered, properly balanced, and free from surface damage and contamination. If this is not the case, vibration must occur, which will cause chatter and reduce tool life and surface finish.

Not all tools need to be balanced to be correct, especially when the processing process causes cost increases and additional steps. Whether to perform tool balancing depends on the specific situation. The balance effect is most prominent at high speeds, but at any speed, balanced tools produce better shape and position accuracy, improve surface finish and extend tool life.

Balancing tools produce the best parts

Although it requires some extra time and care, a proper balance will extend the life of your tool and spindle and increase the available time, and it will produce accurate and high-quality parts for customers.

This article comes from: Dongguan Guorui Cutting Tools Co., Ltd.www.mjocut.com

Mobile QR code

Official account

Applet