Focus on tool design and R & D

Precision cutting tools from Germanymanufacturer

+86 133-9231-4699

Focus on tool design and R & D

+86 133-9231-4699

The goal pursued by cutting is high precision, high efficiency, low cost, and environmental protection. In recent years, cutting processing technology has developed rapidly in the fields of high-speed cutting, hard cutting, micro-mist lubrication cutting, dry cutting, composite cutting, etc. These cutting processing technologies are to achieve the production of high-efficiency and low-cost processing parts with minimal production equipment. The core of the method, so far, the biggest sign of the development of cutting processing technology is the development of high-speed cutting (HighSpeedCutting, HSC).

Advanced tool technology is the basis and guarantee for promoting the development of cutting technology. The development of tool technology involves the development of tool materials and tool structures. Tool materials are the basis for improving tool performance, and tool structure is the key to improving workpiece machining accuracy.

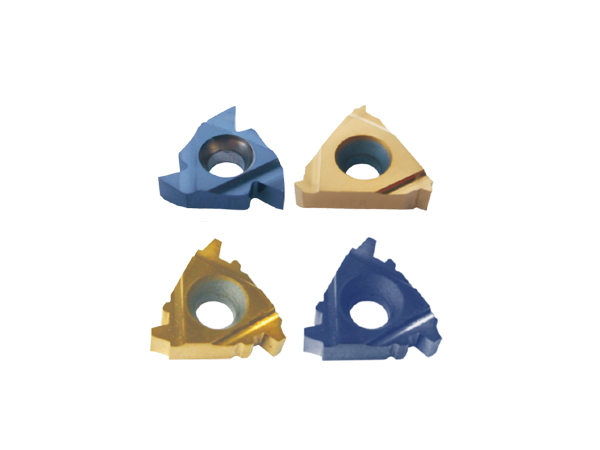

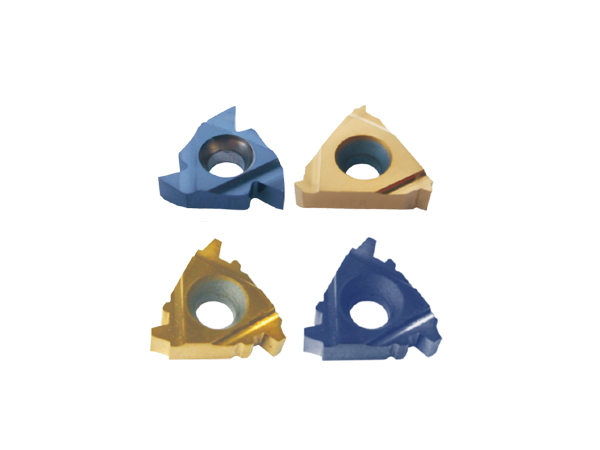

With the advancement of high-speed machining, high-precision machining technology and the increase in the number of difficult-to-machine materials, the progress of tool materials is also very significant, new ceramics, fine-grained cemented carbide, ultra-fine-grained cemented carbide, Materials such as TiC/TiN-based cermet and coated cemented carbide have greatly improved the performance of the tool, and the wear resistance, heat resistance, toughness and bending strength of the tool matrix have been significantly improved. The composite coating technology further improves the tool performance. In addition to TiC, TiN, TiAlN suitable for high-speed cutting, the coating materials now also use diamond, cubic boron nitride, silicon-based nano-coating, etc.

In recent years, people have done a lot of research and application work in the application of new tool materials, tool coating technology and new tool cutting performance. The state of mature application of coatings, the main development trend of future tool materials is "fine-grained matrix material + composite coating" to meet the basic needs of high-speed cutting, dry cutting, and high-precision machining.

Cutting accuracy and surface quality are key factors in the cutting process. Machining accuracy and surface quality depend on the blade shape of the tool, chip breaking performance and the stability of the installation structure. The design of future tools must pay attention to the edge design, chip breaker design, blade positioning or tool holder clamping design, as well as surface coating and cutting edge strengthening treatment.

In order to reduce the application cost of the tool, the insert structure, inlay structure, and coating structure should become the main structure of the tool, and the overall structure should only be used in small and micro specifications. The future tool should have a dual performance structure, that is, "high toughness and high strength matrix + high hardness and high wear resistance edge".

The development of tool materials and coating technology has promoted the continuous improvement of tool cutting speed, brought about the transformation of processing efficiency, and further brought about the expansion of processing range.

The design and use of the tool should consider the performance matching of the tool material and the workpiece material, and determine the reasonable tool material and structure for different workpiece materials and processing conditions. High-speed, high-efficiency, and high-precision cutting requires tools with a variety of excellent properties. "High toughness and high strength matrix + high hardness and high wear resistance edge" is the main development direction of future tools.

Mobile QR code

Official account

Applet