Focus on tool design and R & D

Precision cutting tools from Germanymanufacturer

+86 133-9231-4699

Focus on tool design and R & D

+86 133-9231-4699

For milling stainless steel, except for end mills and some end mills and cemented carbide milling cutter materials, all other types of milling cutters are made of high-speed steel, especially tungsten-molybdenum and high-vanadium high-speed steel with good results. Durability is 1 to 2 times higher than W18Cr4V. The cemented carbide grades suitable for manufacturing stainless steel milling cutters are YG8, YW2,813,798, YS2T, YS30, YS25, etc.

The spray cooling effect is the most significant, which can more than double the durability of the milling cutter; if a general 10% emulsion is used for cooling, the flow of cutting fluid should be sufficiently cooled. When milling cemented carbide with cemented carbide milling cutter, take Vc=70~150m/min, Vf=37.5~150mm/min, and adjust according to alloy grade and workpiece material.

Stainless steel has strong adhesion and fusion, and chips are easy to adhere to the cutting edge of the milling cutter, which worsens the cutting conditions. When milling, the cutting edge first slides on the hardened surface, which increases the tendency of work hardening; the impact vibration during milling is large, which makes the milling cutter blades prone to chipping and wear.

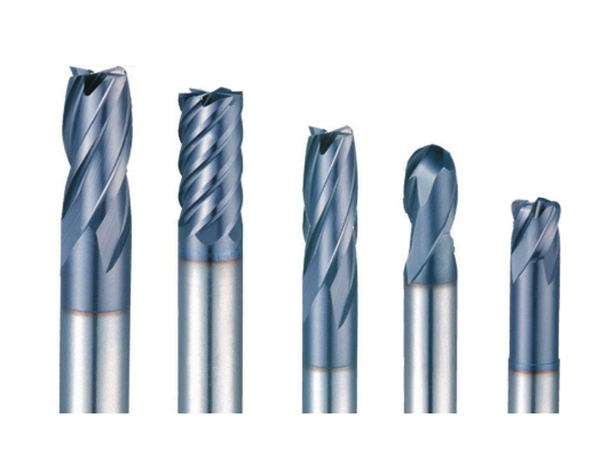

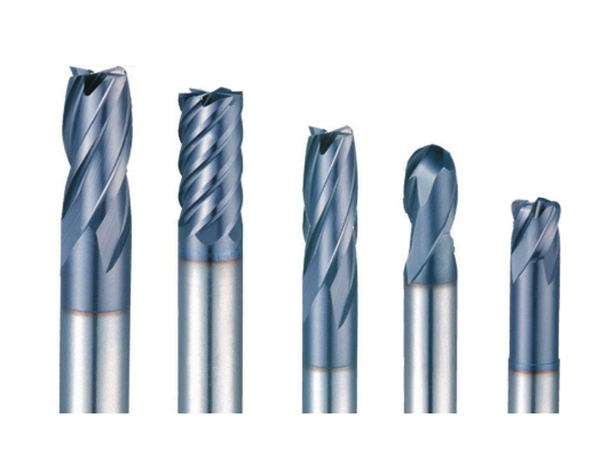

When milling stainless steel, the cutting edge must be sharp and withstand the impact, and the chip flute should be large. Large helix angle milling cutters (cylindrical milling cutters, end milling cutters) can be used. The screw angle b is increased from 20° to 45° (gn=5°), and since the milling cutter is working at this time, the tool durability can be increased by more than 2 times. The rake angle g0e increases from 11° to more than 27°, and the milling is very light. However, the value of b should not be very large, especially for end mills, b≤35°, so as not to weaken the teeth.

Stainless steel pipes or thin-walled parts are processed by corrugated end mills, with light cutting, low vibration, brittle chips, and no deformation of the workpiece. Carbide end mills are used for high-speed milling, and indexable end mills are used to mill stainless steel, which has achieved good results.

Use a silver stand with geometric parameters gf=5°, gp=15°, af=15°, ap=5°, kr=55°, k'r=35°, g01=-30°, bg=0.4 The milling cutter mills 1Cr18Ni9Timm, re=6mm, when Vc=50~90m/min, Vf=630~750mm/min, a'p=2~6mm, the feed per tooth reaches 0.4~0.8mm, the milling force is reduced. The smaller 10% to 15%, the milling power is reduced by 44%, and the efficiency is greatly improved. The principle is to grind the negative chamfer on the main cutting edge, and artificially generate a combined edge during the milling process, so that it can be cut instead of the cutting edge. Due to the lead angle, the rake angle gb of the combined edge can reach 20~302. The effect is that the combined edge becomes an auxiliary chip by the thrust generated by the rake face parallel to the cutting edge, thereby taking away the cutting heat and reducing the cutting temperature.

When milling stainless steel, the same method should be used. The asymmetric cross milling method can ensure that the cutting edge and the metal are smoothly cut off, the chip contact area is small, and it is easily broken under the action of high-speed centrifugal force, so that when the tooth re-cuts into the workpiece, the chip will hit the rake face. Peeling and cutting improve the durability of the tool.

Stainless steel materials are widely used and may be encountered in machining, milling, drilling and tapping. However, due to the different characteristics of stainless steel and other ordinary materials, processing stainless steel has become a major problem for technicians!

Mobile QR code

Official account

Applet